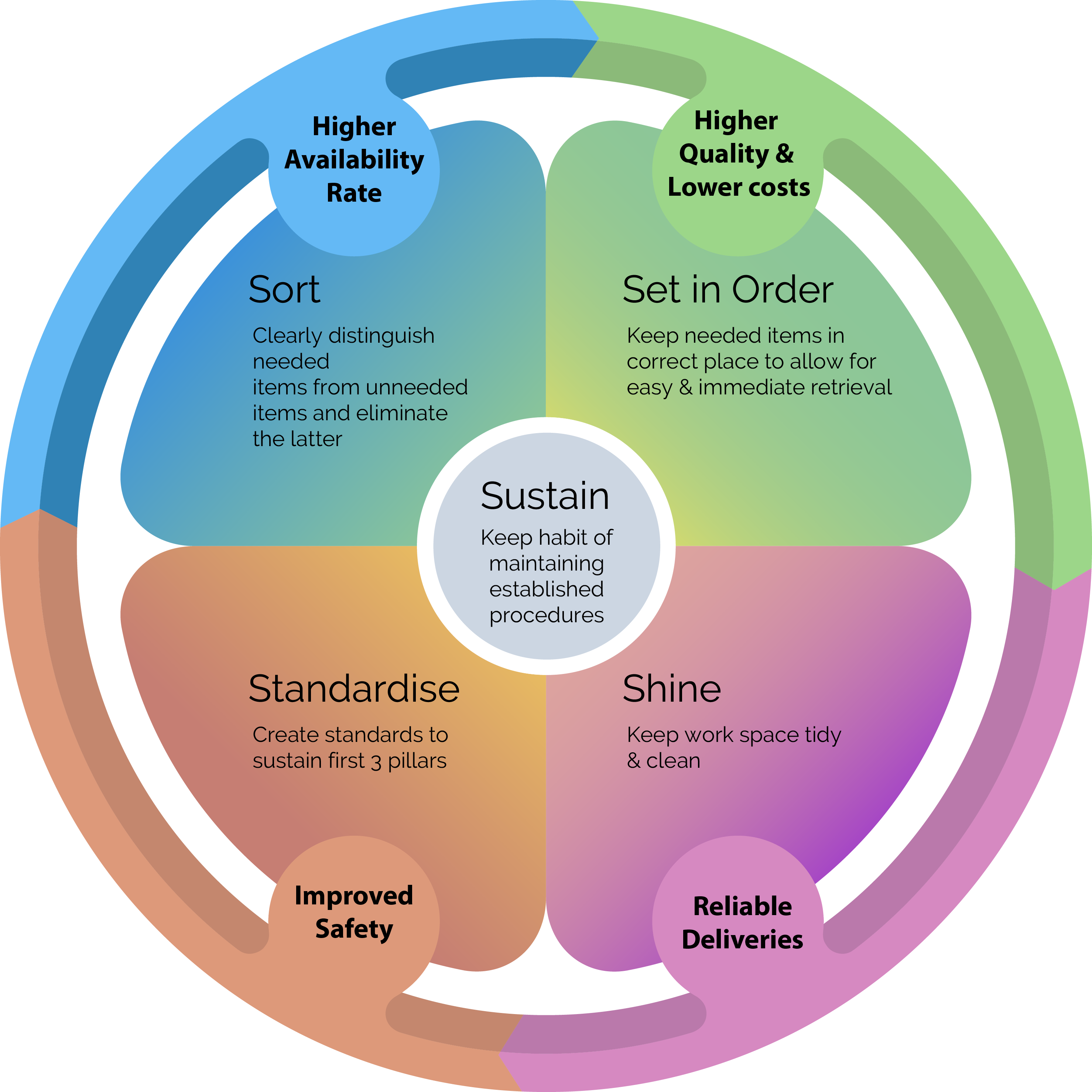

Method and Implementation ApproachĥS is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. 5S provides the foundation on which other lean methods, such as TPM, cellular manufacturing, just-in-time production, and six sigma can be introduced. It also would result in the organization of tools and materials into labeled and color coded storage locations, as well as "kits" that contain just what is needed to perform a task. This lean method encourages workers to improve their working conditions and helps them to learn to reduce waste, unplanned downtime, and in-process inventory.Ī typical 5S implementation would result in significant reductions in the square footage of space needed for existing operations. In the daily work of a company, routines that maintain organization and orderliness are essential to a smooth and efficient flow of activities. The 5S pillars, Sort ( Seiri), Set in Order ( Seiton), Shine ( Seiso), Standardize ( Seiketsu), and Sustain ( Shitsuke), provide a methodology for organizing, cleaning, developing, and sustaining a productive work environment. Implementation of this method "cleans up" and organizes the workplace basically in its existing configuration, and it is typically the first lean method which organizations implement. 5S is a system to reduce waste and optimize productivity through maintaining an orderly workplace and using visual cues to achieve more consistent operational results.

0 kommentar(er)

0 kommentar(er)